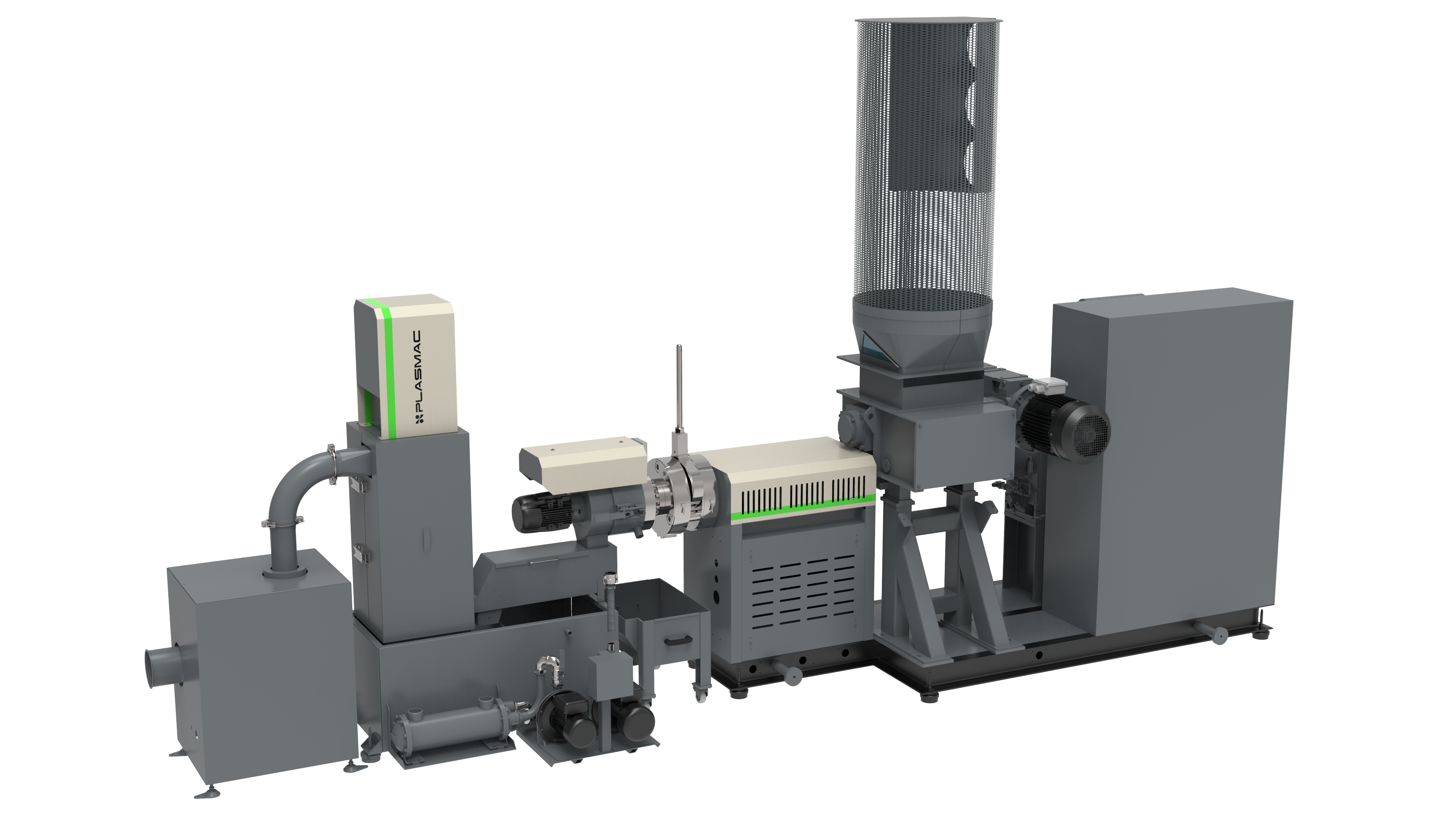

Plasmac has added a new range of Post-Industrial Plastic Scrap Reclamation machinery to its portfolio of effective, energy-efficient recycling machines for post-industrial plastic waste.

The Epsilon range is based around a dual-diameter screw and direct shredder feeding system. A single shaft shredder is mounted on top of the hopper entry. The shredder is cantilevered for easy access to the screw and for cleaning. The shredder is particularly useful for pre-size reduction of some types of feedstock, such as rigid polymers, skeletal waste, thicker trims, and film off-cuts and cut-outs.

At the smaller end of the range, the Epsilon machines are perfect to be used as high-speed inline trim recycling machines or for thicker trims.

The larger Epsilon machines are ideal for the recycling of start-up scrap, injection moulding scrap, and for the recycling of non-wovens.

Depending on the application, Plasmac offers two types of pelletising systems, either AIRCOOL or HYDROCOOL. Normally, the smaller machines would be AIRCOOL and the larger machines can be supplied either AIRCOOL OR HYDROCOOL.

There are a number of standard options available to ensure that this system is perfect for your needs and our team are happy to discuss these with you.