Plasmac – recycling your scrap material

Recycle scrap, reduce the cost, re-use the material. Reclaim your scrap with a Plasmac Repelletiser

A range of powerful scrap reclamation solutions for plastics processors requiring effective post-industrial scrap and trim reclamation in order to maximise their competitive edge.

Scrap reclamation systems designed and manufactured by engineers with years of experience. Supported in the UK with efficient installation, training and after-sales back up.

Low shear, minimum process dwell time and the absolute minimal material degradation enables you to recycle all your scrap material into high-quality pellets, reducing your material costs.

The smallest footprint scrap reclamation machine for extruders on the market, freeing up valuable space for other applications.

ALL MACHINES ARE INSTALLED AND COMMISSIONED BY OUR UK BASED ENGINEERS. WE ALSO PROVIDE ONGOING PREVENTATIVE MAINTENANCE AND SPARE PARTS SERVICE.

Continue on down the page for videos of these recycling systems working with different materials.

These demonstrate the recycling systems working with different materials. We also showcase studies that detail the return on investment.

Principle of Operation

The waste material is directly fed onto the screw, with no prior size reduction required. Because of this little or no dust is produced, with the effect that a higher quality pellet is produced with the lowest level of gels possible.

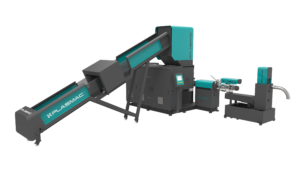

Alpha XS

Utilising Plasmac’s patented Short Screw Technology (SST) based around a dual diameter 8:1 L/D ratio screw.

- Minimal power consumption and the highest output / kW installed power in the market.

- Low shear, minimum process dwell time, minimum material degradation = improved profitability

- Extrusion design, no prior size reduction required.

- Smallest footprint extrusion machine available on the market.

- Perfect for in-line trim recycling.

- Available in air-cooled and water-cooled designs

- Select from manual or fully automatic screen-changers.

- Trim basket optional for feeding inline trims directly into the extruder

- Reelfeed optional for feeding reels or scrap reels directly into the extruder

- Supatrim – for conveying tacky materials

- Flakefeed – to feed in pre size reduced flakes or chips

Alpha

Utilising Plasmac’s patented Short Screw Technology which ensures:

- Minimal power consumption

- Low shear

- Minimum process dwell time.

- Absolute minimal material degradation.

- Highest output / kW installed power in the market.

- Extrusion design, no prior size reduction required.

- Perfect for in-line trim recycling.

- Will also process films, reels, injection moulding parts

- Tailor your Alpha for every application

- Available in air-cooled and water-cooled designs

- Select from manual, continuous, backflush or full automatic screen-changers.

- SY-View HMI Control frees up operators to run other plant operations

- Smallest footprint extrusion machine available on the market.

Omega

Utilising Plasmac’s patented Short Screw Technology

- CAN RECYCLE NEARLY ANY FORM OF WASTE MATERIAL

- PATENTED SHREDDER SCREEN DESIGN

- AUTOMATED START-UP, RUNNING AND SHUT DOWN CONTROL

- Can be supplied non-vented or vented with a single or double vent.

- Multiple feed systems available, including elevator with integrated metal detector, roll-feed or trim basket feed

- Available in air-cooled (up to the Omega 180) and water-cooled designs.

- Select from manual, continuous, backflush or full automatic screenchangers.

- SY-View HMI Control

- Smallest footprint extrusion machine available on the market.

Epsilon

Based on the existing ‘Alpha’ pelletisers, detailed above. This new unit has an integral, single shaft, shredder positioned above the feed throat. This additional shredder can be useful for pre-size reduction of some types of feedstock, such as rigid polymers, skeletal waste, thicker trims, and film off-cuts and cut-outs. It is also a perfect solution for non-wovens loose waste, masks, and cut-out waste from bag and apron making machines.

- The Epsilon range of machines is based around a dual-diameter screw and direct shredder feeding system.

- Market-leading output per kilowatt of installed power (between 3.5 and 5.0 kg/kW)

- Low shear, minimum process dwell time, and the absolute minimal material degradation

- A small footprint, saving valuable floor space

Powerfeed

Minimal power consumption & the highest output / kW installed power in the market – gives you lower running costs so improves your return on investment.

- Variety of sizes to suit all applications and needs with fully customisable configuration

- Fully integrated solution that ensures the trims arrive at the extruder in a perfect condition to repelletise

- Can convey all types of trims from standard trims, tacky trims, trims with PIB up to high speed trims.

- A turnkey solution meaning Plasmac takes care of both your trim conveying and repelletising requirements. Meaning one point of responsibility.

- Trims are delivered with the minimum of air exhaust. Meaning there are no hang-ups, or balling of the trims causing bridging in the extruder, ensures the maximum uptime of your repelletiser.

- Low noise and low power consumption, allows you to install the blower within your production hall. The results in the easiest installation and low power consumption ensures power savings and the best return on your investment. Variable speed control of the blower allows you to tailor the air flow.

- A simple, rugged design that just works. It means your operators can concentrate on running the extrusion line and not on handling trims.