Case Study: Samco Upgrades Biodegradable Film Production with Syncro Technology

Client: Samco Agricultural Manufacturing Ltd

Location: Adare, Co. Limerick, Ireland

Industry: Agricultural Film Production

Upgrade Partner: UK Extrusion & Syncro Group

Focus: COEX Blown Film Line Upgrade

Overview

Samco Agricultural Manufacturing Ltd is at the forefront of sustainable agriculture, supplying innovative biodegradable mulch films to farmers around the world. As part of their commitment to continuous improvement, Samco recently upgraded one of their COEX blown film lines in partnership with UK Extrusion and Syncro Group.

The goal was clear: improve throughput, enhance film quality, and boost operational reliability, particularly when producing delicate biodegradable films.

The Challenge

The original auxiliary equipment on Samco’s COEX blown film line delivered a line speed of 80 m/min and a throughput of 125 kg/h. While suitable for conventional materials, the system struggled to meet Samco’s increasing production goals and tighter quality tolerances for biodegradable films.

The Solution

Samco worked closely with UK Extrusion and Syncro Group to implement a custom upgrade package, incorporating three advanced Syncro technologies:

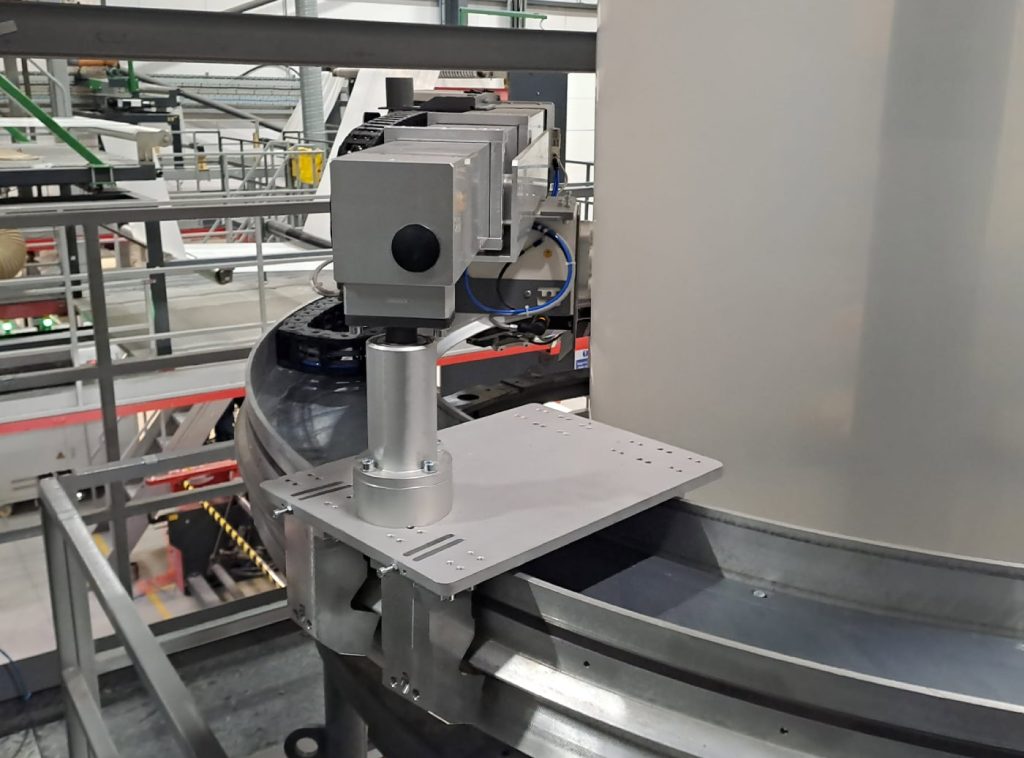

- TYPHOON Y2-048 Automatic Air Ring: Designed with a lightweight carbon fibre chamber and a tailor-made lip-set, the air ring provided precise flow control and bubble stability, crucial for biodegradable materials.

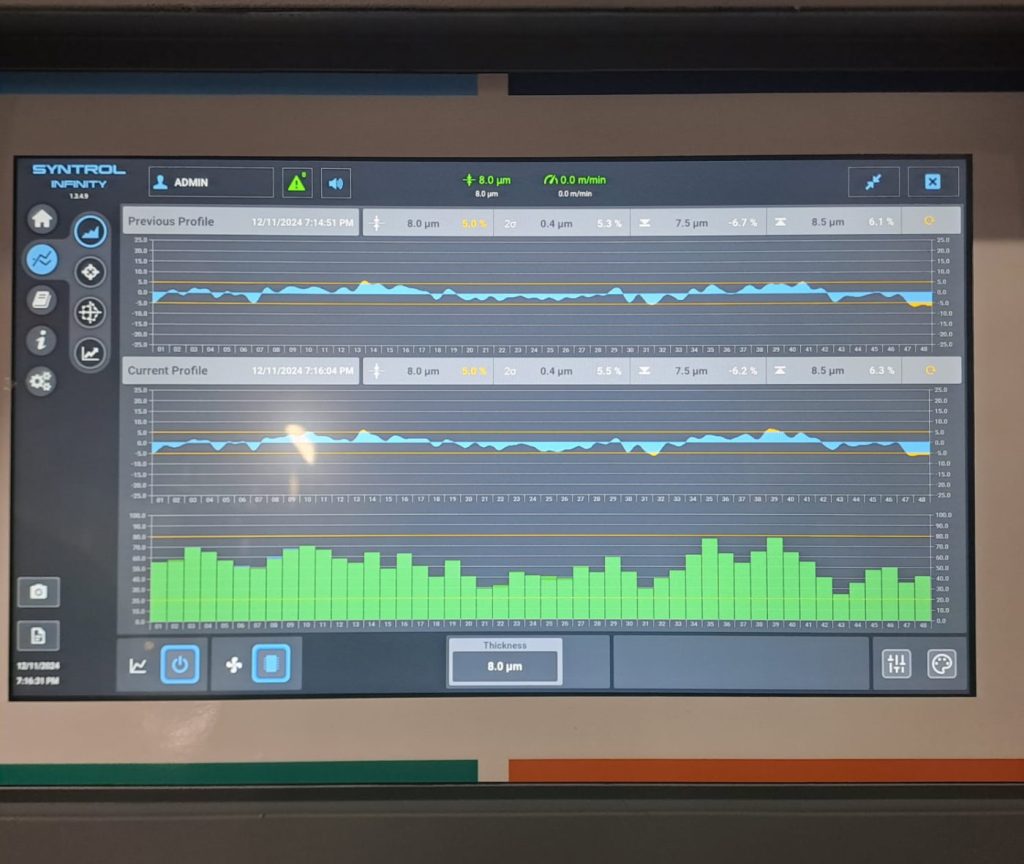

- SKYMEX Non-Contact Capacitive Measurement System: This system allowed real-time thickness monitoring without touching the film, helping to maintain consistent 8-micron film thickness with an impressive ±0.4 micron accuracy.

- SYNTROL INFINITY Supervisory System: An intelligent control platform that automates profile adjustment and improves monitoring, reducing manual intervention and enhancing overall process efficiency.

The Result

The Syncro upgrade delivered exceptional results:

- 30% increase in production

- New line speed: 110 m/min

- Increased throughput: 180 kg/h

- Improved film consistency and accuracy

This marks the third time Samco has upgraded with Syncro components, highlighting their long-standing trust in Syncro’s advanced technology and UK Extrusion’s local support.

Ready to Modernise Your Blown Film Line?

Whether you’re working with biodegradable materials or aiming to improve line speed, consistency, and efficiency, UK Extrusion and Syncro can help. Contact us today to discuss your requirements.