Case Study: Microwave Dryer Technology Transforms PET Film Recycling

Customer Application: A leading film manufacturer supplying the food, pharmaceutical, automotive, and electronics sectors was facing major issues with its PET drying process. Using a traditional gas-powered crystalliser, the customer experienced high energy consumption, unsuitable drying for dusty internal regrind, and a large footprint on the shop floor.

The Challenge:

- Material: PET – including pellet, bottle flakes, and dusty internal film regrind

- Issues:

- High energy consumption (0.9 kWh/kg)

- Agglomeration problems with film regrind

- Moisture levels around 300ppm

- Crystalliser required excessive floor space

- Reduced IV (Intrinsic Viscosity) post-extrusion

The Solution:

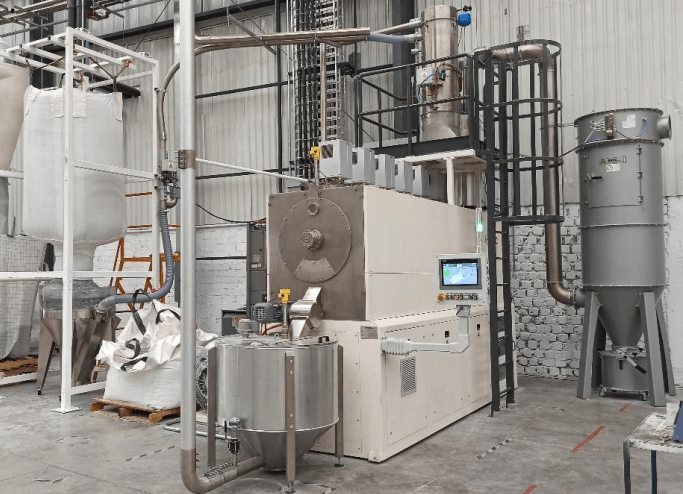

UK Extrusion supplied an SMC MWD1000 Microwave Dryer, replacing the existing crystalliser. This cutting-edge system combines crystallisation and drying in a single, compact unit.

Performance Improvements:

- Energy Efficiency: Reduced to 0.70 kWh/kg – a 23% saving

- Productivity:

- Regrind & bottle flakes drying to ≤ 50ppm moisture

- Throughput: 1,000 kg/h

- Mono-screw extrusion output increased by 20%

- IV Retention:

- Before MWD: 0.59–0.61 dl/g

- After MWD: 0.68–0.70 dl/g

- Space Saving: Smaller footprint freed up valuable production space

- Process Flexibility: Enabled 100% use of in-house PET film regrind

The Result:

By switching to the SMC microwave dryer, the customer achieved substantial energy savings, improved product quality, and boosted extrusion output—all while reducing their factory footprint.

Looking to improve your PET recycling process?

Contact UK Extrusion today to learn how we can help can boost your output, reduce energy costs, and maximise regrind usage.