Rigid Sheet Extrusion Lines

Precision-Engineered for Durable, High-Output Sheet Production

Bandera’s high-performance rigid sheet extrusion lines are designed to serve the evolving needs of packaging, converting, and thermoforming markets. With the flexibility to process a wide range of materials—including PET (R-PET), C-PET, PET-G, PP, PS, and PLA—these lines are built to deliver exceptional quality, efficiency, and adaptability.

Every line can be customised to meet your exact production requirements, whether you’re targeting lightweight, multi-layer structures or food-grade packaging film.

Rigid Sheet applications

Rigid Sheet Lines for Demanding End-Use Markets

Bandera’s rigid sheet extrusion lines are ideal for producing:

- Thermoformed trays, containers, and blister packs

- Food-grade packaging and lids

- Multi-layer composite sheets

- Lightweight structural foam film (VelPET®)

- Converting and lamination base films

- Form-Fill-Seal (FFS) packaging systems

Whether you’re manufacturing short production runs or high-volume orders, Bandera provides a versatile solution for your downstream applications.

Bandera Rigid Sheet Product Range

Tailored Lines for

Every Rigid Sheet Requirement

Whether you’re producing thermoforming sheet, industrial trays, or multilayer packaging, Bandera has a trusted solution. Explore the full range available through UK Extrusion.

Alpha Lines

Robust, High-Output Lines for Premium Applications

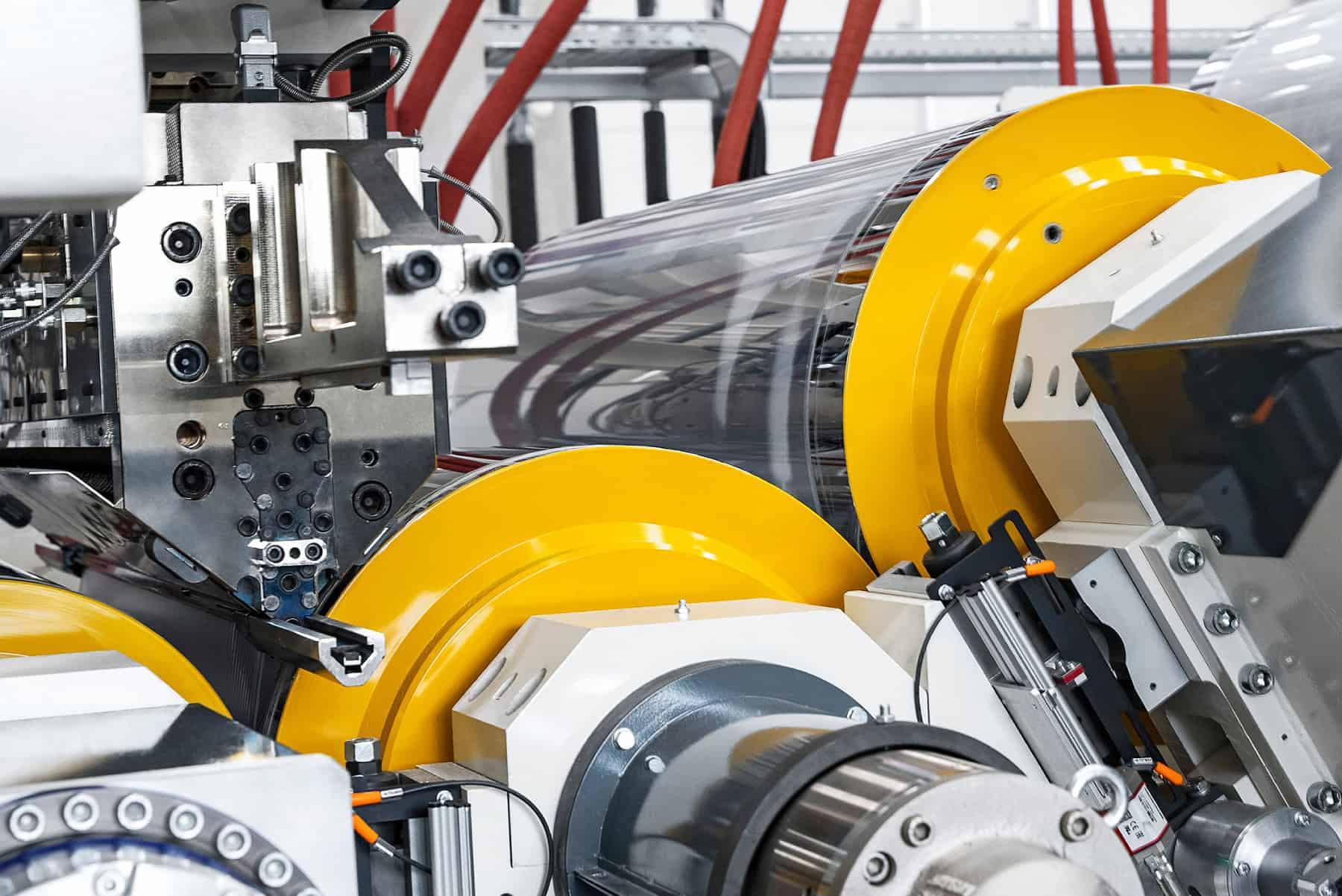

Alpha Lines are engineered for flexibility, performance, and durability. With the ability to handle wide format production and a broad thickness range, these systems offer the ideal foundation for high-output, multi-application manufacturing.

Key features:

- Sturdy calender roll stack for 0.12 mm to 1.60 mm film thickness

- Net widths up to 2000 mm and outputs up to 3000 kg/h

- In-calender and off-calender lamination systems

- Extrusion coating capabilities for composite products

- VelPET® technology for structural E-PET foam production

PURe PET Food Grade Lines

Certified Performance for Food-Grade Packaging

Designed to meet the most stringent global standards, PURe PET lines work in tandem with Bandera’s HVTSE™ Highly Vented Twin Screw Extruders to produce FDA and EFSA-compliant PET sheet.

Key features:

- High-performance, energy-efficient design

- Cost-effective without compromising quality

- Insulated extrusion buffer for improved energy usage

- Plug & Play system with integrated raw material conveying

- Easy access for inspection and maintenance

Agility Lines

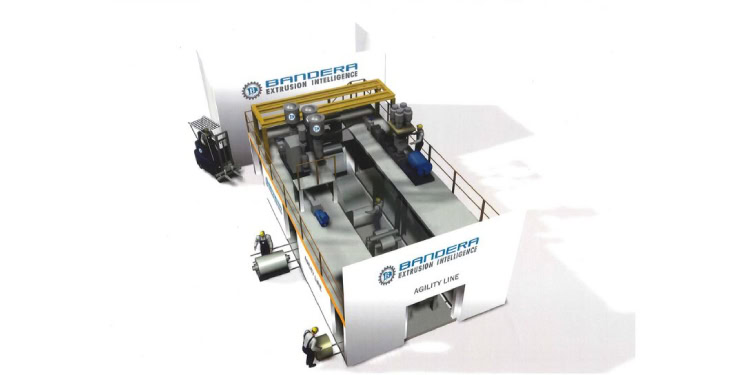

Compact, Flexible Systems for Fast Turnaround Production

Ideal for FFS and short-run, high-quality applications, Agility Lines feature a compact two-floor structure, enabling quick installation and fast changeovers—without sacrificing output or quality.

Key features:

- Modular Plug & Play installation on just 85 sqm

- Quick start-up with fully automated thread-in operation

- Operator-friendly interface with minimal training required

- Medium output range up to 600 kg/h

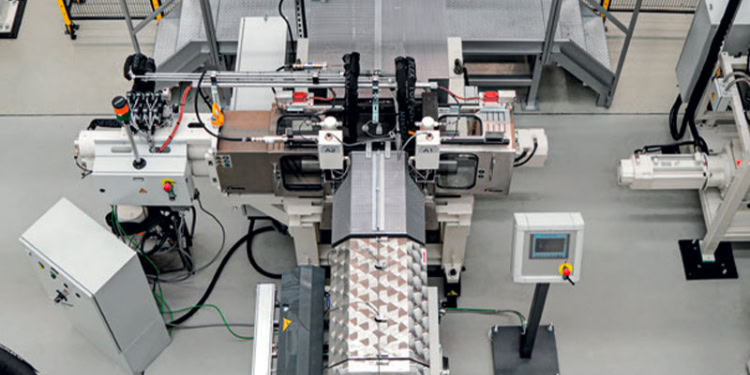

SmartDuty Lines

Proven Performance for Food and Industrial Packaging

SmartDuty® is one of Bandera’s bestselling rigid sheet extrusion solutions, known for its reliability, repeatability, and cost-effectiveness. Designed with the latest food packaging demands in mind, these medium-output lines are ideal for thermoforming and Form-Fill-Seal applications.

Key features:

- Output capacities of 700–1000 kg/h

- Operator-friendly design for ease of use

- Covers the full range of packaging thicknesses and widths

- Compact footprint with quick installation

- Compatible with in-line thermoforming systems (via strategic partners)

- Supports VelPET® structural E-PET foam film for lightweight, recyclable packaging solutions

Backed by UK Extrusion

Local support global expertise

As the exclusive UK and Ireland agent for Bandera, UK Extrusion offers more than just cutting-edge machinery. Our team of UK-based engineers provides full installation, commissioning, and ongoing support, including preventative maintenance and spare parts supply.

We’re on hand to guide you at every stage, from specification and line layout to training and production optimisation. Whether you’re investing in a new line or upgrading an existing system, we provide technical expertise and responsive aftercare to keep your operation running smoothly. With UK Extrusion, you get the benefits of world-class Italian engineering backed by reliable, local support.

get in touch

Let’s Talk Rigid Sheet Solutions

Speak to our team today about how Bandera’s technology could improve your production performance.