Recycling & Repelletising Machines

Smart recycling solutions for plastic processors

Reclaiming and repurposing scrap plastic is no longer just an environmental priority, it’s a commercial advantage. UK Extrusion supplies a full range of recycling and repelletising machinery designed to help processors recover value from waste materials while meeting strict regulatory and quality requirements.

We work exclusively with two leading European technology partners, Bandera and Plasmac, to bring you systems for both post-consumer and post-industrial recycling. These machines are engineered to deliver high-quality, cost-effective pellets with minimal material degradation, whether you’re operating in packaging, extrusion, injection moulding, or compounding.

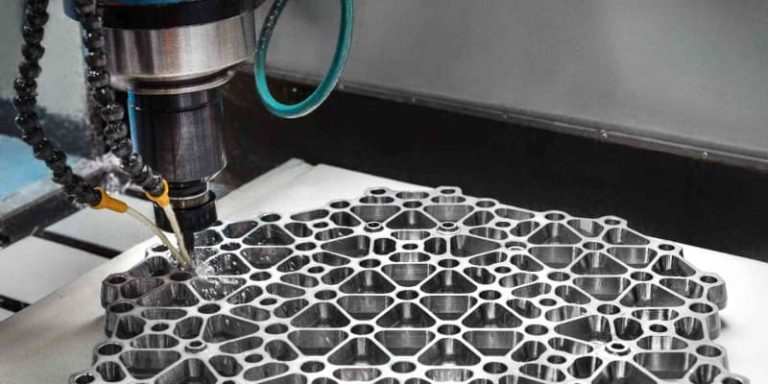

Recycling & Repelletising applications

Suitable for a wide range of plastic waste streams

Our range of recycling technologies is suitable for:

- In-line and off-line post-industrial scrap recovery

- Film, sheet, and injection moulding waste

- Edge trims, reels, and skeletal waste

- Rigid polymers, non-wovens, and bag cut-outs

- Food-grade PET recycling (FDA and EFSA compliant)

- Bottle-to-bottle and tray-to-tray recycling

- Polypropylene and polyethylene up-cycling

Plasmac Product Range Range

From Plasmac

Recycle POST INDUSTRIAL WASTE with a compact, efficient, low energy solution

Alpha / Alpha XS

Plasmac’s patented Short Screw Technology delivers market-leading output-to-kW ratios with minimal material degradation. Ideal for in-line trim recycling. Compact footprint and no pre-size reduction required.

Omega

Heavy-duty off-line pelletising system capable of processing virtually any plastic waste. Offers fully automated operation, patented screen design, and multiple feeding configurations.

Epsilon

Alpha-based design with integrated shredder for rigid polymers, thick trims, and non-woven offcuts. Perfect for applications requiring pre-size reduction.

Powerfeed

Trim conveying system engineered for maximum uptime and efficient feeding of even tacky or high-speed trims. Variable blower speed and minimal noise for easy integration.

Bandera Product Range Range

From Bandera

Recycle POST CONSUMER WASTE with RevoTECH Recycling Technologies

Co-Rotating Twin Screw Systems

Designed for processing well-selected, pre-washed post-consumer polyolefins with high levels of degassing, super filtration, and excellent energy efficiency. Includes under-water pelletising and melt flow index control.

Cascade Systems

Twin extruder configuration ideal for heavily contaminated feedstock. Features two-stage filtration and degassing, virgin/additive blending, de-odourising, and fast colour changes—perfect for producing "second use virgin" pellets.

HVTSE PET Extrusion

Highly Vented Twin Screw Extruders offer powerful melt purification for 100% regrind PET, with low shear and no pre-drying required.

PURe Food-Grade Rigid Film Systems

FDA and EFSA-approved solid-state decontamination, ultra-low energy use, and market-leading IV stability. Can operate standalone or inline.

Bottle-to-Bottle Recycling Lines

Combines PURe and HVTSE for the production of super-clean PET pellets suitable for food-grade bottles.

Tray-to-Tray Recycling Lines

Enables the recycling of PET trays into new mono-material trays with full recyclability and excellent sealing properties—eliminating the need for multi-material films.

Backed by UK Extrusion

Local support global expertise

Every recycling system is installed and commissioned by our UK-based engineers, ensuring smooth start-up and on-site training. We also offer full after-sales support, preventative maintenance, and spare parts supply to keep your systems running at peak performance.

get in touch

Talk to us about your recycling goals

Whether you’re reclaiming trim waste or aiming for food-grade PET, we can recommend the best solution for your operation.