Laboratory & Pilot Extrusion Lines

Benchtop & Small-Batch Solutions for R&D & Quality Testing

UK Extrusion supplies a complete range of laboratory and pilot extrusion lines from EUR.EX.MA, built specifically for recipe development, small-scale production, and material testing. Designed for research and quality control environments, these compact, high-precision systems are trusted by global plastic processors, recyclers, and compounders to test new formulations under real-world conditions.

Laboratory & Pilot applications

Purpose bult for Lab, Pilot & R&D Environments

EUR.EX.MA’s lab and pilot-scale extrusion lines are ideal for:

- Quality control and formulation testing

- Development of new polymers and biopolymers

- Research for packaging, medical, and industrial films

- Filament and yarn testing for 3D printing and textiles

- Recycled material and masterbatch evaluation

- Small-batch sample production for customer approvals

EUR.EX.MA Laboratory & Pilot Product Range

Scalable Solutions for

Research & Small-Scale Production

Whether you’re developing new materials, testing processing conditions, or scaling up from lab to production, EUR.EX.MA offers a range of precision-engineered systems to suit your requirements. Explore the compact, high-performance lines available through UK Extrusion.

Cast Film Lines

Versatile Film Samples for Quality Testing

Designed to produce film samples across a wide variety of thermoplastic polymers, these compact cast film lines support thicknesses ranging from 20 to 300 microns. Ideal for lab-based evaluation of film properties and performance.

Blown Film Lines

Mono & Multilayer Tubular Film Testing

These laboratory-scale lines enable the extrusion of mono-layer or up to 7-layer blown film, supporting R&D in packaging, medical, and high-performance film sectors. Built for flexibility, with easy changeover and minimal material waste.

Compounding Lines

Compact Solutions for Material Formulation

MicroEx CP and CP Twin lines are benchtop compounding systems built for testing and quality control of recycled polymers, masterbatches, additives, and biopolymers. The twin-screw version enhances mixing performance and allows optional degassing and screw configuration changes.

3D Filament Lines

Precision Filament Testing in Low Volumes

MicroEx 3D and 3D Plus systems are tailored for filament extrusion using different polymer grades and blends. Designed to minimise waste, they allow rapid testing of formulations before entering serial production.

Melt Spinning Lines

Full-Drawn-Yarn Sample Production

The MicroEx SP is a bench-scale system that allows small sample production of melt-spun yarns. Perfect for testing fibre characteristics with low resource usage and fast material changeover.

Injection Moulding Line

Material & Colour Testing on a Compact Scale

The MicroEx MD injection moulding system is ideal for creating test plaques and samples for analysis. Commonly used for polymer, colour, and additive trials with minimal energy usage and material waste.

Optional Add-On for Defect Reduction

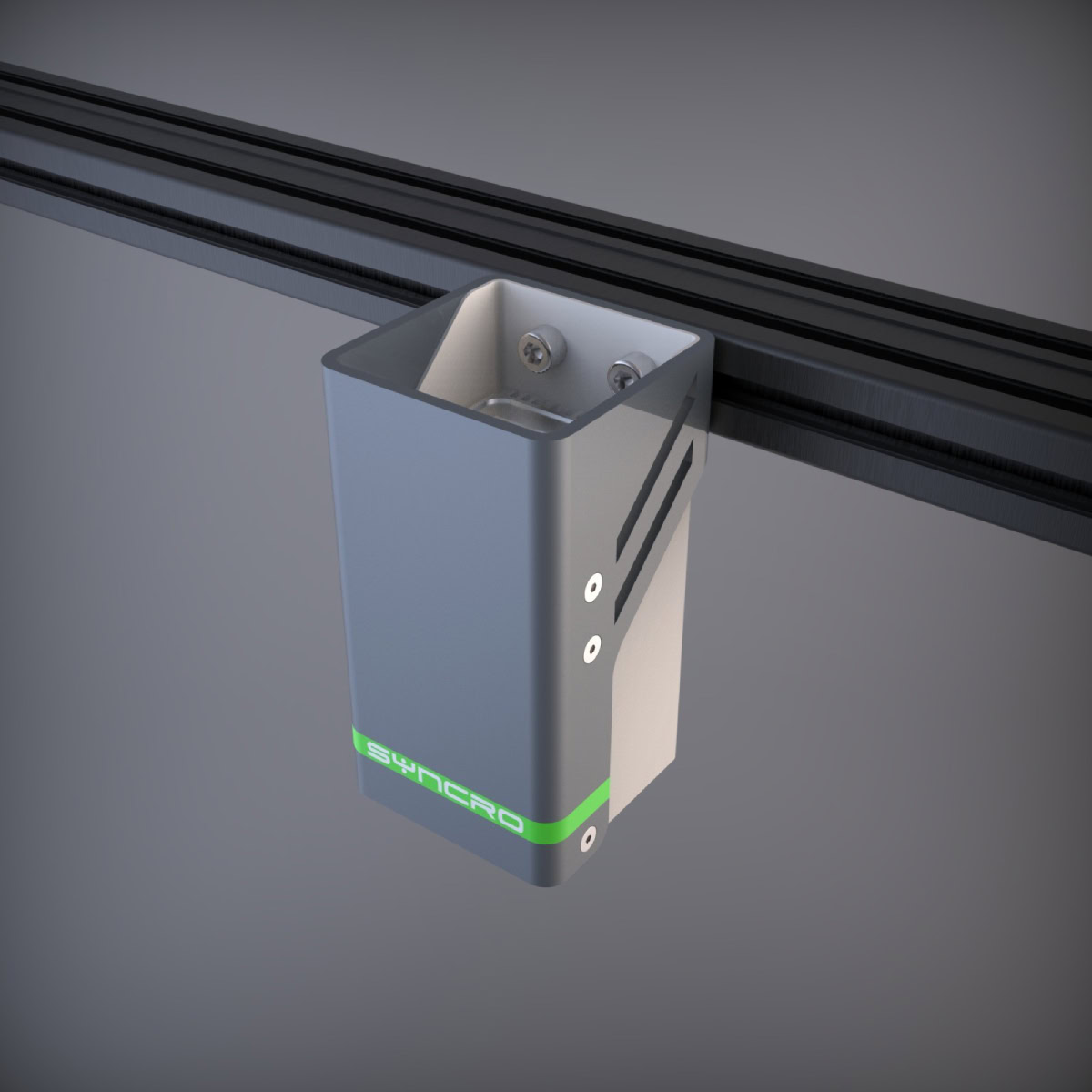

Syncro EYES Web Inspection

Enhance your testing capabilities with real-time visual inspection and defect tracking. The Syncro EYES system is an optional add-on that integrates seamlessly with EUR.EX.MA laboratory and pilot lines, providing precise monitoring during both extrusion and converting processes.

This intelligent system identifies and classifies surface defects, including gels, black spots, holes, and inclusions, allowing for immediate correction and reducing material waste. By capturing detailed data in real time, Syncro EYES helps maintain the integrity of each sample and supports faster development of high-quality film and sheet products.

End-to-End Support

See the technology in action

EUR.EX.MA operate a dedicated demo and testing centre, EUR.EX.LAB, where you can trial materials, explore equipment configurations, and evaluate sample output before purchase. It’s a great way to see the process firsthand and ensure your solution is perfectly tailored to your needs.

Speak to the UK Extrusion team today about how EUR.EX.MA systems can support your R&D and testing processes.

Local support global expertise

As the exclusive UK and Ireland distributor for EUR.EX.MA, UK Extrusion offers complete local support, including installation, commissioning, training, and servicing, carried out by our experienced UK-based engineering team.

We also provide ongoing preventative maintenance and access to genuine spare parts, giving you full confidence in the reliability and long-term performance of your lab-scale systems.

get in touch

Ready to Upgrade Your Film Production?

Talk to our team today about Bandera’s blown film systems and find the perfect solution for your process. Get in touch to discuss the right Bandera blown film solution for your business.