Continuous & Hydraulic Screen Changers

Screen changers that protect product quality

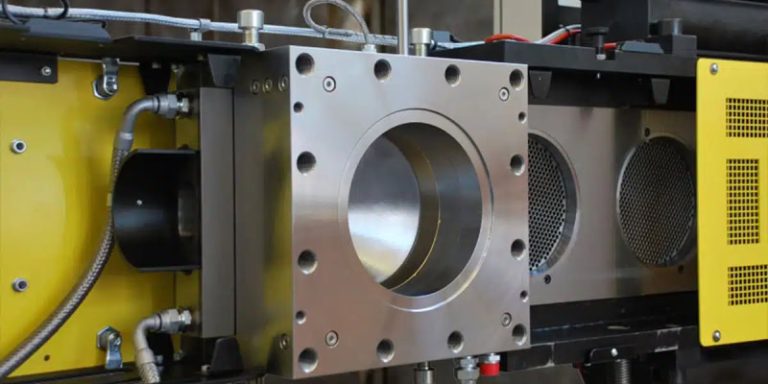

Screen changers are a vital component in any extrusion line, used to filter out contaminants from the polymer melt before it reaches the die. Clean, consistent polymer flow is essential to ensure high product quality, prevent equipment damage, and maintain process efficiency. Over time, filter screens become blocked with impurities and must be replaced regularly. The method and speed of screen replacement can significantly impact output rates, product consistency, and overall running costs.

UK Extrusion supplies advanced screen changers from BD Plast, a globally recognised manufacturer of downstream extrusion technology. From cost-effective manual systems to fully automatic continuous flow solutions, BD Plast screen changers are engineered for precision, durability, and easy maintenance across a wide range of applications.

Screen Changers applications

Built for every polymer processing challenge

BD Plast screen changers are suitable for use in:

- Blown and cast film production

- Flat sheet extrusion

- Pipe and profile extrusion

- Cable coating

- Masterbatch and compound pelletising

- Pelletising from polymerisation

- Blow and injection moulding

- Hot melt adhesives

Whether you’re running virgin or recycled materials, BD Plast systems help maintain optimal filtration without compromising productivity.

BD Plast Screen Changer Range

Engineered Solutions for

Every Output Requirement

From manual lever-operated models to high-performance continuous flow systems, BD Plast offers a screen changer to suit every production need. Each model is engineered for easy maintenance, long service life, and minimal process disruption.

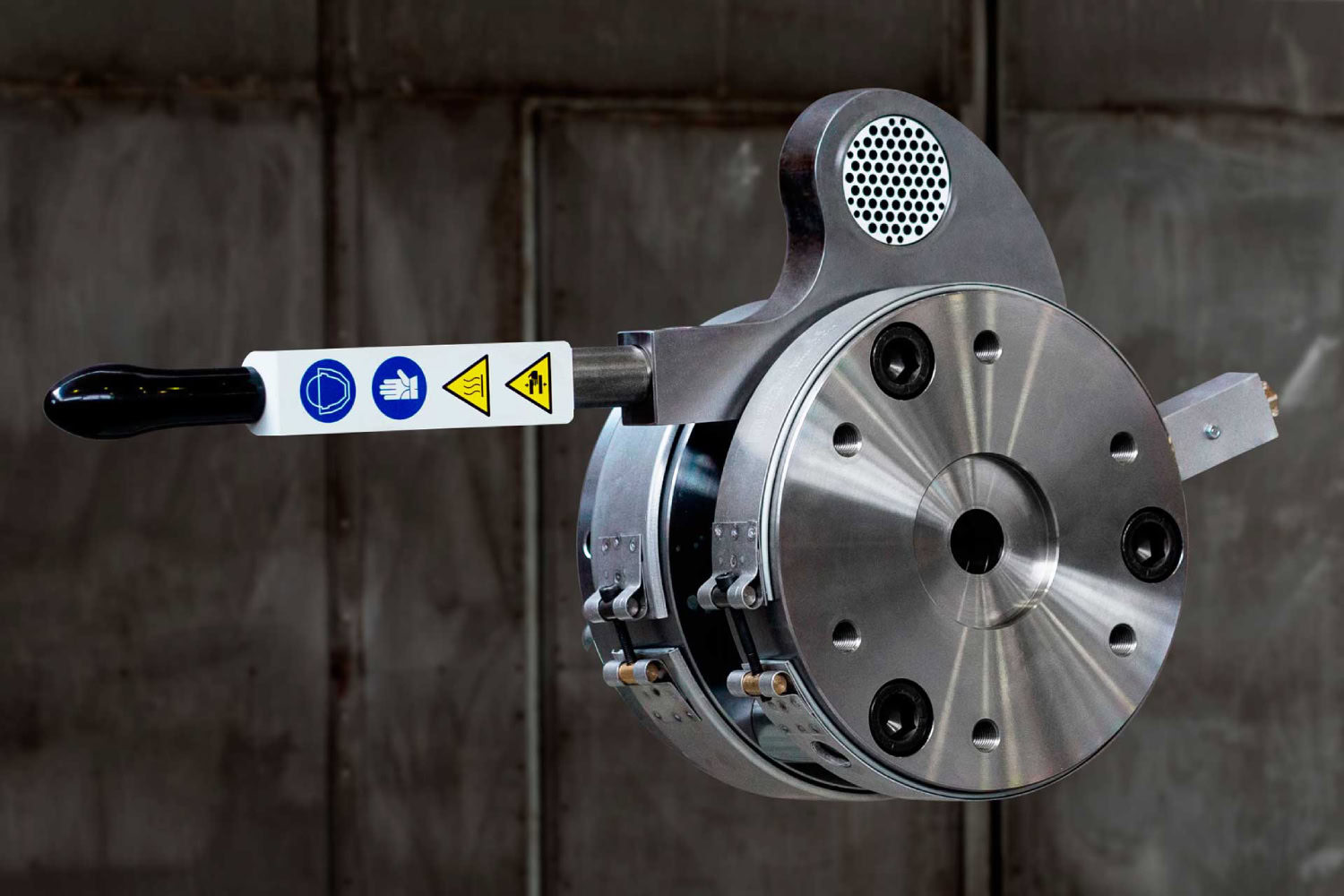

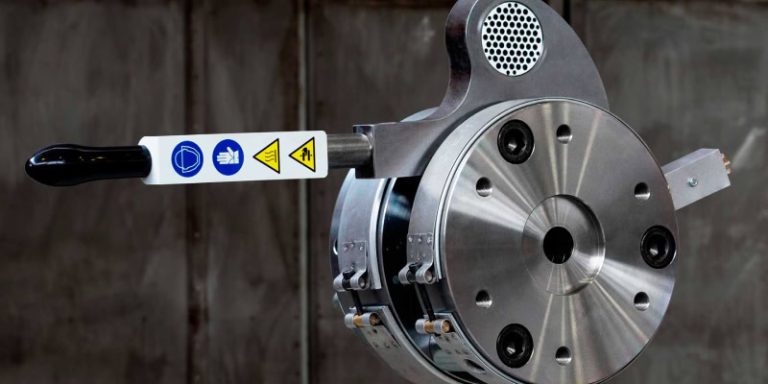

BDL

Lever-Type Manual Screen Changers

Simple and cost-effective, ideal for small and medium-sized lines. Available in Ø 20–120 mm filter sizes, with a self-activating sealing system and 3-sided manoeuvrable lever for fast screen changes.

BDLG

Ratchet-Type Manual Screen Changers

A step up in performance and build quality for larger manual systems. Available in Ø 45–250 mm filter sizes, offering leakproof sealing and high reliability.

BDP

Manually Operated Hydraulic Screen Changers

Hydraulic upgrade of manual systems. Equipped with temperature control on each filter holder and cable channel protection, these systems offer improved ergonomics and process stability.

BDO FT

Fully Hydraulic Screen Changers

Designed for high-output lines requiring frequent screen changes without stopping production. Quick-change hydraulic systems ensure minimal downtime and maximum reliability.

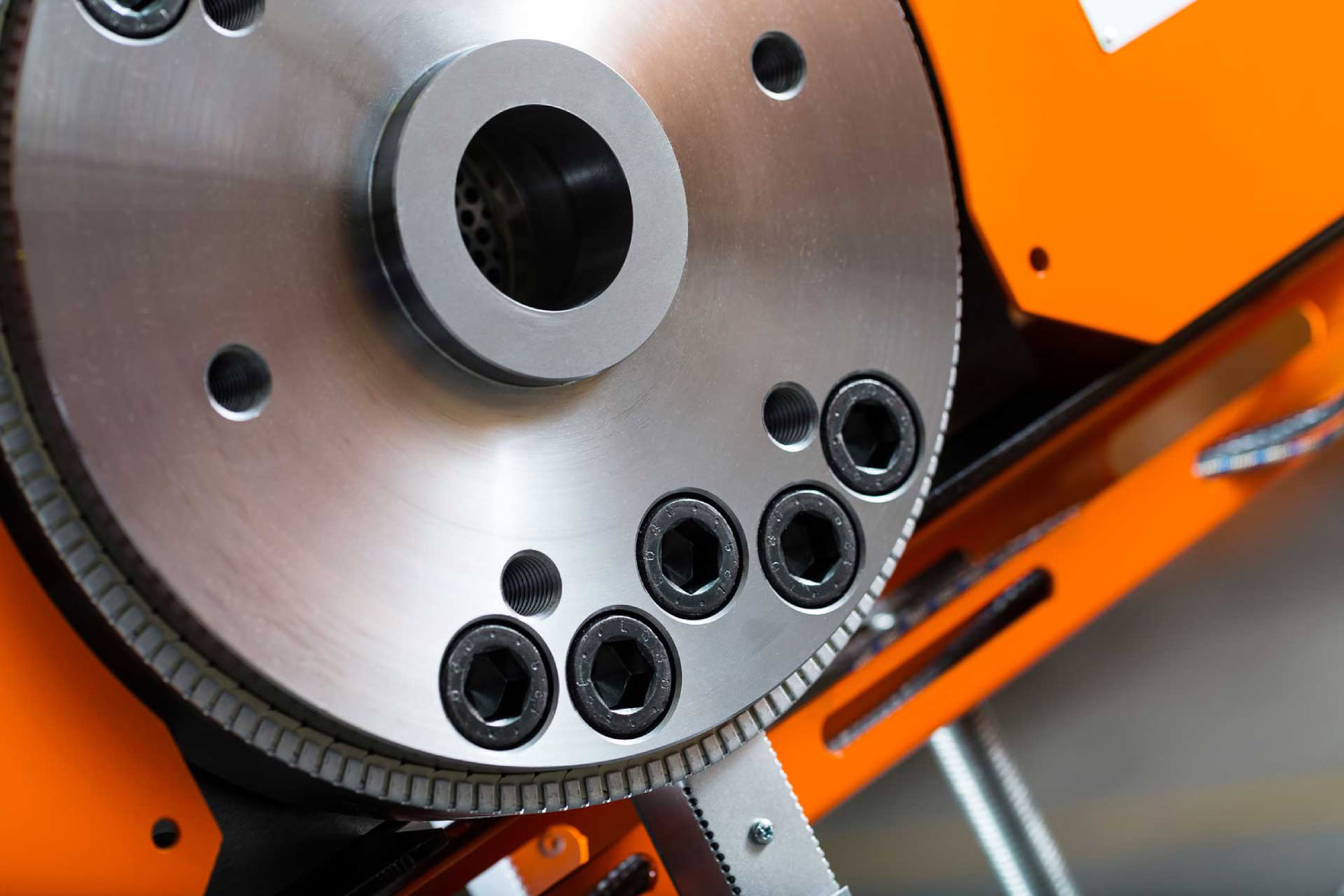

BDO FQ

High-Performance Hydraulic Screen Changers

Engineered for demanding applications such as recycling, with filtering areas up to Ø 450 mm. Delivers durability, versatility, and consistent filtration at scale.

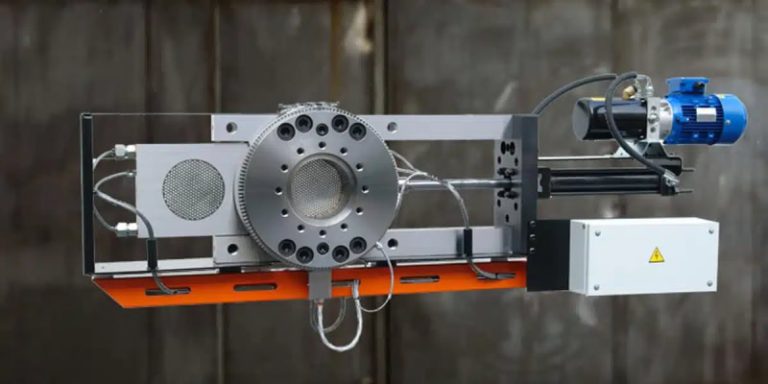

BDOx2

Continuous Flow Hydraulic Screen Changers

Maintain uninterrupted production, even at high pressures. These advanced screen changers feature an innovative sealing system and interchangeable components for simplified servicing.

Backed by UK Extrusion

Local support. global expertise.

UK Extrusion is the exclusive partner for BD Plast in the UK and Ireland. Our team provides full technical support, installation, and aftersales service – ensuring that your screen changer system is properly integrated and maintained from day one.

All BD Plast equipment is installed and commissioned by experienced UK-based engineers, with optional preventative maintenance packages and spare parts support to maximise uptime and equipment lifespan.

get in touch

Ready to upgrade your filtration system?

Get in touch with UK Extrusion today, to find the right BD Plast screen changer for your extrusion line.