Gauging & Measurement Systems

Inline measurement for tighter control, reduced waste, & consistent quality

UK Extrusion supplies advanced gauging and measurement systems from Syncro, designed to ensure accuracy and repeatability throughout the extrusion process. These high-performance systems provide real-time data on film thickness, layer distribution, optical properties, and surface quality, helping processors maintain tight tolerances and reduce material waste.

Whether you’re producing blown film, cast film, or sheet, Syncro’s inline measurement systems support quality assurance, improve product uniformity, and enable automatic process control.

Gauging & Measurement Systems applications

For Extrusion Processes Where Precision Matters

Syncro’s gauging and inspection technologies are widely used in:

- Blown and cast film production

- Multilayer film extrusion

- Flat sheet extrusion

- Optical film and barrier packaging

- Technical films requiring precise layer distribution

- Extrusion processes demanding inline quality inspection and data recording

These systems enable detailed measurement of parameters like thickness, haze, gloss, surface defects, and optical density, allowing for early detection of issues and consistent output.

SYNCRO Gauging & Measurement Systems

Full suite of

inline measurement technologies

Take a closer look at Syncro’s advanced gauging and measurement systems. Designed for inline precision, each solution helps optimise output, reduce waste, and maintain the highest production standards.

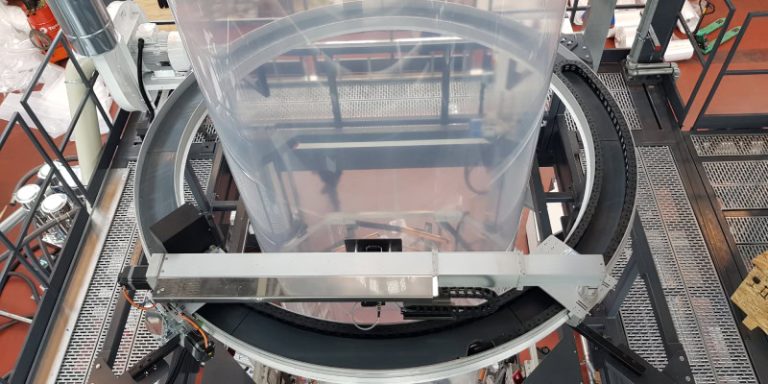

SKYMEX

A non-contact infrared scanner for thickness measurement of mono and multi-layer film. Designed for both blown and cast film lines, SKYMEX uses dual IR sensors to measure barrier and non-barrier materials simultaneously with high precision.

OPTYLAYER

Measures the thickness of each layer in coextruded films. It uses dual non-contact sensors and advanced algorithms to provide a detailed breakdown of each layer, ensuring accurate barrier and structural properties.

OPTYMEC

Designed for optical inspection of film and sheet surfaces, measuring haze and gloss to verify product aesthetics and transparency, especially in optical and food-grade applications.

SHADYSCAN

A versatile backscatter X-ray gauge for non-intrusive thickness measurement, ideal for thicker films and sheets where traditional methods struggle to penetrate accurately.

COMBYSCAN

A hybrid system combining multiple measurement technologies—such as IR, beta, and X-ray—into one compact platform for highly accurate layer and total thickness analysis across a range of film types.

OPTYSCAN

Syncro’s optical surface scanner designed to detect surface defects such as gels, black spots, and inclusions. An essential system for quality control on high-clarity or technical films.

RAYXSCAN

X-ray gauging system for total thickness and weight per area measurement, designed for use with high-output lines or materials with variable optical properties.

BYTASCAN

Syncro’s high-speed camera inspection system, designed to capture and analyse visual defects such as wrinkles, scratches, and contamination in real time with high resolution and reliability.

Backed by UK Extrusion

Local support global expertise

Every Syncro gauging system is installed and commissioned by our UK-based engineering team, ensuring seamless integration and immediate operational readiness. UK Extrusion also provides operator training, preventative maintenance programmes, and a fast-response spare parts service to minimise downtime and protect your investment long term.

get in touch

Ready to improve product quality & process control?

Contact us today to discuss your requirements and benefit from expert advice, local support, and high-performance technology tailored to your production goals.